Big Dipper Case Studies

Big Dipper® automatic grease traps let restaurants and commercial kitchens operate almost anywhere — even in non-traditional spaces where buried interceptors aren’t an option. Compact and efficient, they install right in the kitchen and quietly handle grease removal around the clock.

Each unit features Advanced Odor Protection, sealing in smells that standard traps can’t contain. And because the system automatically skims grease into a separate collector, there’s no need for pump trucks or messy service calls. Staff can empty the container in under two minutes and get right back to work.

With Big Dipper, kitchens stay cleaner, operations run smoother, and compliance is effortless — all in a system built for performance and simplicity. It’s a reliable, low-maintenance solution that helps reduce operating costs, minimize downtime, and keep every kitchen running efficiently day after day.

Check out our case studies below for some real-world examples of Big Dipper in action.

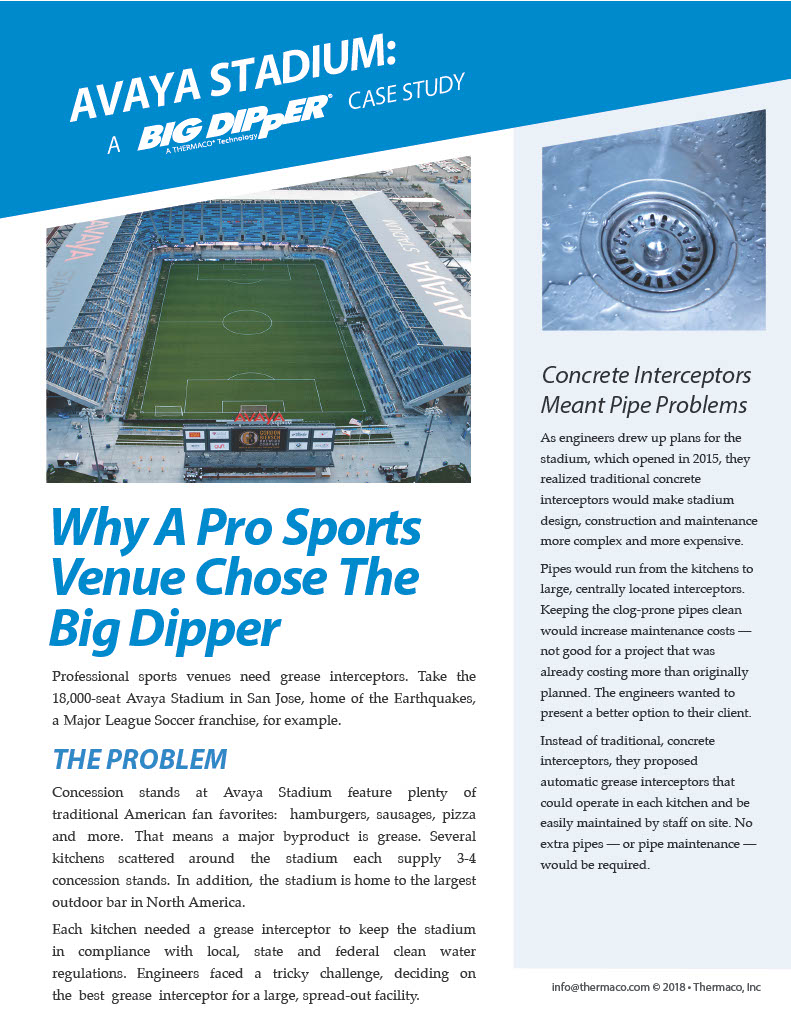

Avaya Stadium Case Study

MLS Earthquakes open a stadium focused on its fans

Problem: When the MLS San Jose Earthquakes began building Avaya Stadium, their goal was clear: create a world-class fan experience with dozens of concession stands serving stadium favorites like pizza, hot dogs, and burgers.

But those fan favorites come with a downside — grease. With multiple kitchens scattered throughout the stadium, the engineering team needed a way to manage grease waste without overcomplicating plumbing or risking costly clogs. Traditional interceptors were too large, too messy, and too difficult to service in such tight spaces. They needed to find a different solution.

Solution: The engineers turned to Big Dipper®. With a range of sizes and flexible installation options, Big Dipper fit perfectly into Avaya Stadium’s space-constrained kitchens.

Each unit automatically removes grease from wastewater and stores it in a sealed collector that staff can easily empty into a rendering barrel — no pump trucks, no downtime, no odor. The system’s simple design and reliable operation made it the clear choice for such a complex layout.

Result: Since opening day, Avaya Stadium has had zero complaints about its Big Dipper units. The kitchens run smoothly, maintenance stays minimal, and the staff can focus on what matters most — serving great food and keeping fans happy.

Life’s Kitchen Case Study

How a non-profit stays focused on their mission

Problem: “You could tell when they were cleaning the grease trap because of the smell,” said Tammy Johnson, Executive Director of Life’s Kitchen. “It was pretty horrible.”

Life’s Kitchen is a culinary training program that helps at-risk youth build confidence, develop practical skills, and create a path toward stability. But one of the most dreaded kitchen chores wasn’t cooking — it was cleaning out the grease trap. The odor alone made the task unpleasant, and it pulled staff and students away from what really mattered: learning and growing through their mentorship program.

Solution: When Thermaco learned about the issue, our team stepped in to help. We donated a Big Dipper® Automatic Grease Collector to make the Life’s Kitchen cafe setup cleaner, safer, and easier to manage.

Unlike traditional traps, the Big Dipper automatically skims grease from the water and stores it in a sealed collector. Staff can simply empty the container in seconds — no scooping, no mess, no smell. With Advanced Odor Protection, the kitchen stays fresh and focused on its mission, not maintenance.

Result: Now, Life’s Kitchen can spend less time cleaning and more time changing lives. The team can focus on preparing young people with the skills, confidence, and experience they need to succeed — while the Big Dipper quietly takes care of the grease.